In the highly competitive food and beverage industry, the efficiency and quality of the packaging process have become crucial for enterprises to gain a foothold in the market. However, many factories are facing difficulties in packaging production. Traditional equipment has poor adaptability when it comes to meeting the packaging needs of various products such as multi-cup packs, pre-packaged cups, and bottled products. It requires long hours of debugging when frequently changing specifications. A large amount of manual operation not only leads to low efficiency but also results in continuous packaging defects, causing high rework and quality inspection costs. Procurement managers in factories are urgently seeking a packaging device that is efficient, stable, and adaptable to diverse production requirements.

Upon in – depth analysis of the industry status, there are three pressing pain points in food and beverage packaging equipment. Firstly, the problem of specification conversion is prominent. Due to the diverse shapes of packaging containers such as bottles and cups and the variety of collective packaging specifications, traditional equipment requires complex adjustments to mechanical components when switching production, leading to prolonged production line downtime. Secondly, packaging quality is unstable. With manual participation in product grouping, positioning, wrapping, and other processes, it is difficult to ensure uniform standards. Problems such as loose and skewed packaging occur frequently, severely affecting the ex – factory quality of products. Thirdly, the degree of equipment intelligence is low. Old – fashioned equipment is not only complex to operate, requiring workers to spend a lot of time learning, but also prone to frequent failures. The high maintenance costs and downtime losses have become a heavy burden on enterprises.

If these packaging pain points persist, enterprises will suffer significant negative impacts. Low packaging efficiency directly leads to delayed order delivery, missed peak sales periods, decreased customer satisfaction, and even customer loss. Packaging quality issues may trigger consumer complaints, damage the brand reputation, and may even lead to serious consequences such as product returns and recalls. High labor and maintenance costs continuously squeeze profit margins, causing enterprises to gradually lose their competitive edge in the fierce market competition.

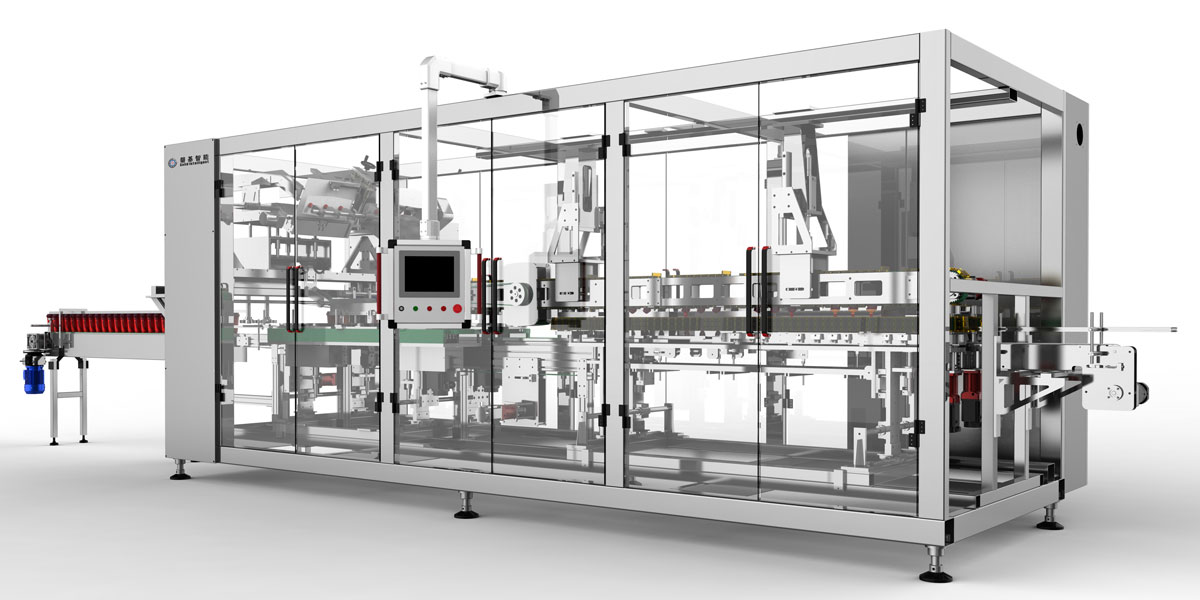

To break through the packaging bottleneck, our multiple models of fully automatic sleeve – type multi – cup paper sheet wrapping machines and non – standard customized food packaging equipment are the ideal choices. The fully automatic sleeve – type wrapping machines, multi – cup wrapping machines, and paper sheet wrapping machines are specifically designed for the post – packaging of multi – cup products, pre – packaged cup products, and bottled products. The entire process, from paperboard picking, product grouping, to folding, gluing, sealing, and output, is fully automated, greatly reducing manual intervention and improving production efficiency and packaging quality stability.

The equipment has significant advantages in technology and performance. The multi – specification collective packaging technology takes full account of the needs of different packaging containers and specifications. The moving parts in contact with the packaging can be adjusted in size, enabling quick conversion between different packaging specifications in a short period. The flexible product grouping technology uses a flexible cup – pressing mechanism and a smooth engineering plastic mesh belt chain to ensure that products such as multi – cup packs are not damaged during the grouping process, safeguarding product integrity. The anti-detachment positioning technology sets exclusive positioning buckles on the paperboard according to the appearance characteristics of different products, accurately positioning the paperboard and products, effectively preventing the problem of package disintegration during transportation and sales. In addition, the main components of the equipment are driven by servo motors, featuring precise movements, high efficiency, and energy conservation. The conveyor belt with a large – capacity paperboard storage function supports continuous paperboard loading without stopping the machine, ensuring production continuity. The dedicated PLC programmable control system, combined with a color digital touch – screen human – machine interface, provides intuitive and easy operation and control, reducing the operation difficulty and training costs for workers.

At the same time, the paperboard packaging materials used by the equipment not only have excellent surface printing effects, enhancing the visual appeal of products, but also have the characteristics of environmental protection and no pollution. They meet the current consumer pursuit of green products and enhance the market competitiveness of enterprise products. As a professional brand with years of experience in the field of food and beverage packaging equipment, we have a professional R & D team and rich experience in non – standard customization. We can tailor exclusive packaging solutions according to the actual needs of enterprises. We provide one – stop services throughout the entire process, from preliminary communication and scheme design to equipment installation, debugging, and after – sales maintenance, escorting the packaging production of enterprises.

Still troubled by packaging problems? Click to consult now, obtain detailed information and customized solutions for multiple models of fully automatic wrapping machines, and embark on a new journey of cost reduction, efficiency improvement, and quality upgrading in food and beverage packaging!

[You Deserve a Better Production Method]

Click to inquire → Get your Customized Food & Beverage Packaging Line Solution

Hangzhou Panji Intelligent Equipment Co., Ltd. Tel/Wechat/Whatsapp +86 18989472188 [email protected]