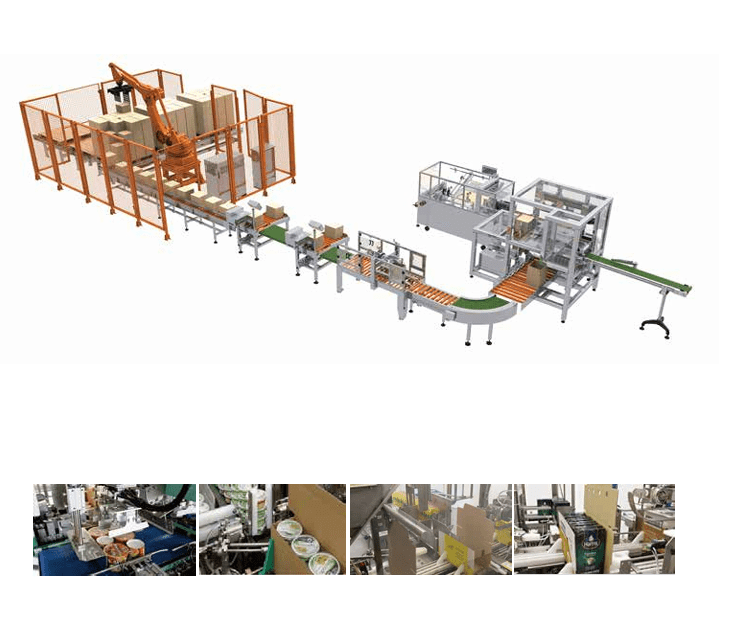

Purchasing managers of factories, are you still troubled by issues of efficiency and stability in finished product stacking at the final stage of food and beverage production? From boxed drinks to bagged raw materials, palletizing, as a key link connecting production and warehousing, traditional manual work or inefficient equipment often becomes a “bottleneck” restricting full-process automation.

Industry Pain Points: Typical Difficulties in Food and Beverage Palletizing

Amplified Consequences: Chain Reactions of Palletizing Shortcomings

Solutions and Brand Advantages: Core Value of Palletizing Robots

Functional Features and Advantages:

If your factory is facing problems such as low palletizing efficiency, high costs, or potential safety hazards, please feel free to consult us. Our palletizing robots will provide customized solutions for food and beverage enterprises to help optimize production processes. Click to consult for equipment parameters and adaptation plans.

[Te mereces un mejor método de producción]

Haga clic para preguntar → Obtenga su comida personalizada & Solución de la línea de embalaje de bebidas

Hangzhou Panji Intelligent Equipment Co., Limitado. Tel/WeChat/WhatsApp +86 18989472188 [email protected]