when planning the production of fruit ball products such as popping boba, magic beans, and crystal balls, are you restricted by issues like low efficiency, difficult flavor switching, and unstable forming that limit production capacity? As a popular innovative ingredient in beverages, milk tea, baking, and other fields, the demand for fruit balls continues to grow. However, traditional production methods often fail to meet the needs of large-scale, multi-category production.

Industry Pain Points: Typical Obstacles in Fruit Ball Production

In the production of fruit ball products like popping boba, magic beans, and crystal balls, do these pain points frequently plague your production line?

• High manual involvement: From juice preparation, titration forming to cleaning and curing, a large number of workers are required for collaboration. This not only results in low efficiency but also easily affects product quality due to human operation errors.

• Unstable forming: It is difficult to accurately control the diameter of fruit balls within the standard range of 5-12mm. The “chewy” texture of the outer membrane is uneven, and some products are prone to breakage, making it impossible to ensure consistent taste for each fruit ball.

• Troublesome flavor switching: When changing flavors such as strawberry, passion fruit, and mango, incomplete equipment cleaning easily causes flavor cross-contamination. Parameter adjustment takes a long time, making it hard to quickly respond to multi-category order demands.

• Dispersed production processes: Equipment for preparation, forming, filling, and other links operates independently, requiring manual transfer and connection. This is prone to contamination, and mismatched rhythms between links lead to low overall efficiency.

• Low automation level: The lack of a unified control system makes production data difficult to trace, failing to meet food production standardization requirements and increasing the difficulty of quality control.

Amplified Consequences: Chain Losses from Production Shortcomings

If these issues are not resolved promptly, the seemingly localized process defects will trigger multiple losses and affect the enterprise’s competitiveness:

• Production Capacity Lag: Manual work and dispersed equipment slow down production speed. Insufficient fruit ball supply causes downstream beverage and baking production lines to stop for materials, missing the peak market period and affecting order delivery.

• Rising Costs: A large number of manual inputs drive up labor costs. High defective rates in forming lead to raw material waste, and additional expenses such as cleaning and rework further squeeze profit margins.

• Quality Risks: Production contamination or unstable forming causes fruit balls to deteriorate or break. Once entering the market, this triggers consumer complaints and damages brand reputation and customer trust.

• Restricted Innovation: Equipment cannot quickly adapt to the production of new flavors and specifications of fruit balls. Enterprises struggle to keep up with market trends (e.g., new products like yogurt magic beans and orange magic beans), missing competitive opportunities.

Solution and Brand Advantages: Core Value of the Automatic Popping Boba Production Machine

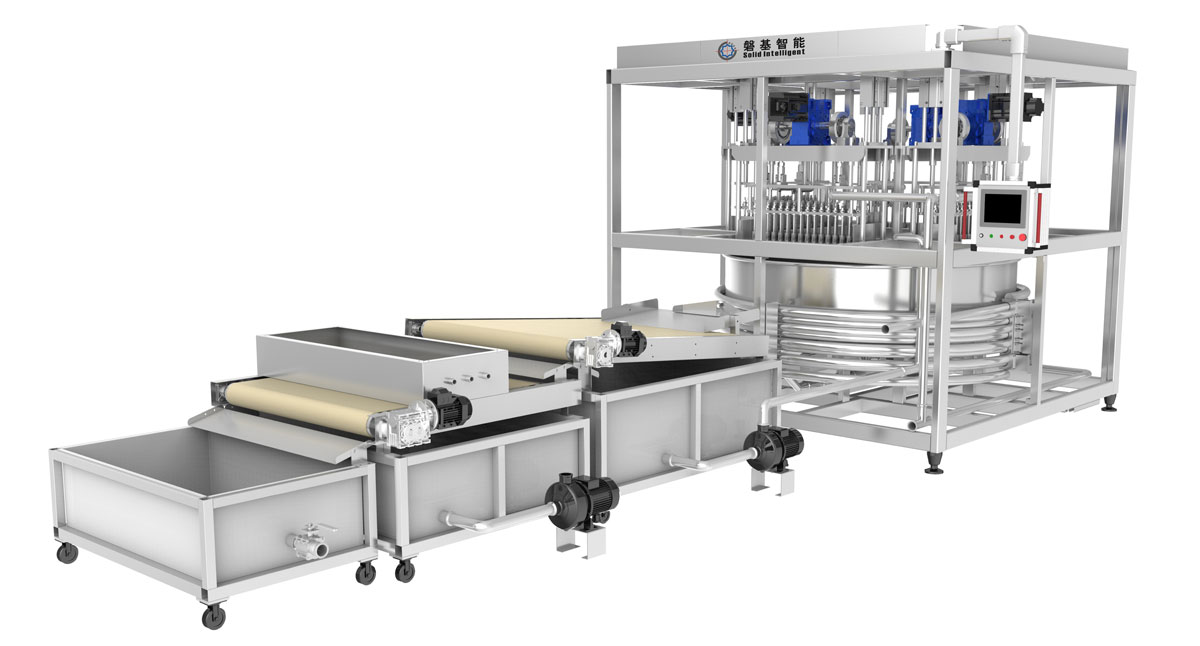

To address the above pain points, our independently developed Automatic Popping Boba Production Machine (with functions for producing popping boba, crystal balls, fruit balls, and magic beans) — as a professional food and beverage packaging equipment — features full-process automated design, providing large and medium-sized enterprises with an efficient, stable solution for fruit ball mass production.

Core Advantages: High Efficiency, Intelligence, and Adaptability to Multi-Scenario Needs

Full-Process Automation for Cost Reduction and Efficiency Improvement: The entire line consists of a raw juice preparation and supply system, titration system, forming system, filtration system, cleaning and curing system, filling and sealing system, sterilization system, and PLC control system. It automatically completes production from raw materials to finished products without extensive manual intervention, significantly improving production efficiency.

• Highly Stable Forming to Ensure Quality: With a single-head forming speed of 60-70 times per minute, the diameter of fruit balls is accurately controlled within 5-12mm. The “chewy” toughness of the outer membrane is uniform, effectively reducing the breakage rate and ensuring consistent taste for each fruit ball, meeting food quality standards.

• Flexible Flavor Switching: Supports the production of fruit balls in multiple flavors such as strawberry, passion fruit, mango, yogurt, and orange. The equipment is easy to clean and parameters can be adjusted simply, enabling quick flavor switching to adapt to multi-category order demands.

• Intelligent Control for Standardized Production: Adopts a PLC control system to monitor production data in real time, facilitating traceability and management. Integrating domestic and foreign technical features, the equipment operates stably with a high level of automation, complying with food production standardization requirements.

• Multi-Functional Adaptability for Scenario Expansion: It is not only suitable for producing popping boba in beverages and milk tea but also can manufacture crystal balls for baking decoration and magic beans for catering seasoning. It meets the needs of multiple scenarios including catering, frozen desserts, baking, and breakfast, helping enterprises expand their product lines.

If your enterprise is troubled by issues like low fruit ball production efficiency, unstable quality, and difficult flavor switching, or plans to deploy production lines for innovative ingredients such as popping boba and magic beans, please feel free to consult us. Our Automatic Popping Boba Production Machine will provide you with a precise solution to support large-scale, high-quality production. Click to consult for equipment parameters, customized plans, and cases.

[You Deserve a Better Production Method]

Click to inquire → Get your Customized Food & Beverage Packaging Line Solution

Hangzhou Panji Intelligent Equipment Co., Ltd. Tel/Wechat/Whatsapp +86 18989472188 [email protected]