Dear Factory Procurement Managers, in the production of bucket instant noodles, bowl instant noodles, vermicelli, or cup noodles, are you often troubled by efficiency and quality issues in the sealing process? As a key process for product freshness preservation and leak prevention, poor-performing sealing equipment not only disrupts production rhythm but also risks damaging product reputation. Traditional sealing methods can no longer meet the needs of large-scale production.

Industry Pain Points: Typical Challenges in Sealing Bucket/Cup Noodles

In the sealing production of bucket instant noodles, bowl vermicelli, and similar products, do these pain points frequently bother you?

• High manual involvement: Multiple workers are required to collaborate in lid suction, lid placement, and sealing. The efficiency fails to match the speed of front-end noodle cake feeding and ingredient addition, easily leading to product backlogs at the sealing stage.

• Uneven sealing temperature control: Some products have loose seals (prone to liquid leakage) while others have overly tight seals (causing paper bowl deformation). The defective rate is relatively high, increasing rework costs.

• Poor equipment adaptability: For paper bowls/plastic bowls with different calibers (100-150mm), frequent mold replacement is required. Adjustment takes a long time, making it impossible to switch product specifications quickly.

• Crooked cup output after sealing: Manual sorting is needed to connect to the subsequent production line, creating an “automation gap” and increasing additional labor costs.

• Lack of comprehensive fault early warning: When equipment malfunctions (such as lid jamming or temperature control failure), there is no timely alert. Troubleshooting takes a long time, reducing the daily effective production duration.

Amplified Consequences: Chain Losses from Sealing Shortcomings

If these seemingly localized sealing issues are not resolved promptly, they will trigger a series of chain losses and put the enterprise in a passive position:

• Production Capacity Lag: Low sealing efficiency slows down the entire production line, affecting order delivery schedules and undermining customer trust in cooperation.

• Rising Costs: Continuous investment in labor costs, plus rework for defective products and raw material waste (e.g., damaged paper bowls, discarded sealing films), further squeezes profit margins.

• Quality Risks: Loose seals cause products to absorb moisture and deteriorate during transportation and storage, leading to higher consumer complaint rates and damaging brand reputation. Deformed paper/plastic bowls entering the market reduce end consumers’ recognition.

• Expansion Restrictions: Equipment cannot quickly adapt to multi-specification products. When enterprises want to expand into product categories such as cup noodles or small-caliber bowl vermicelli, they need to purchase additional equipment repeatedly, resulting in high investment and increased workshop space occupation.

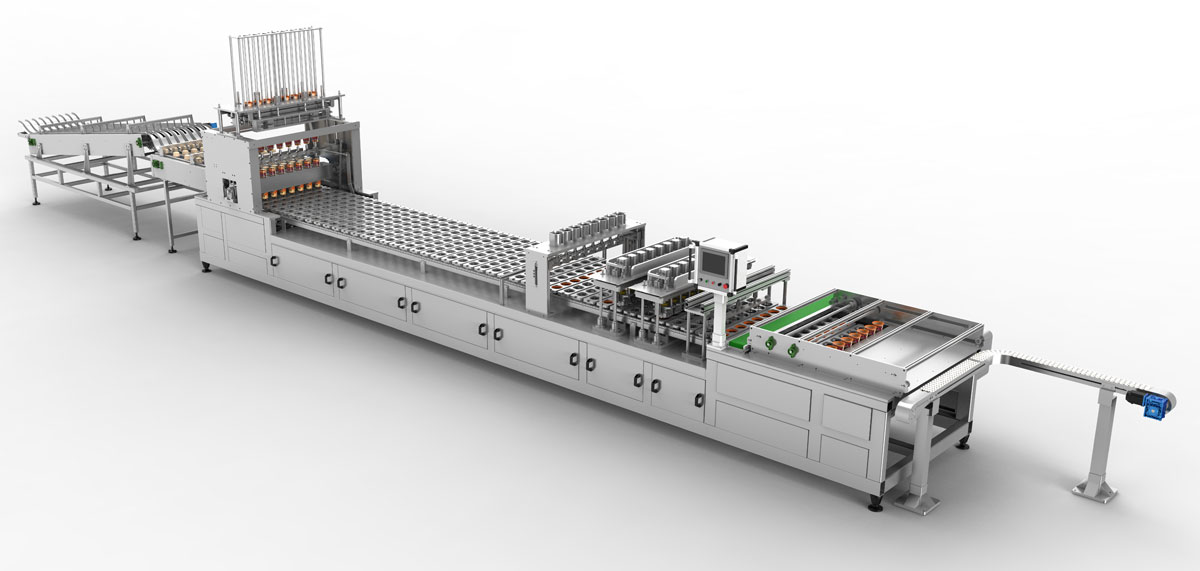

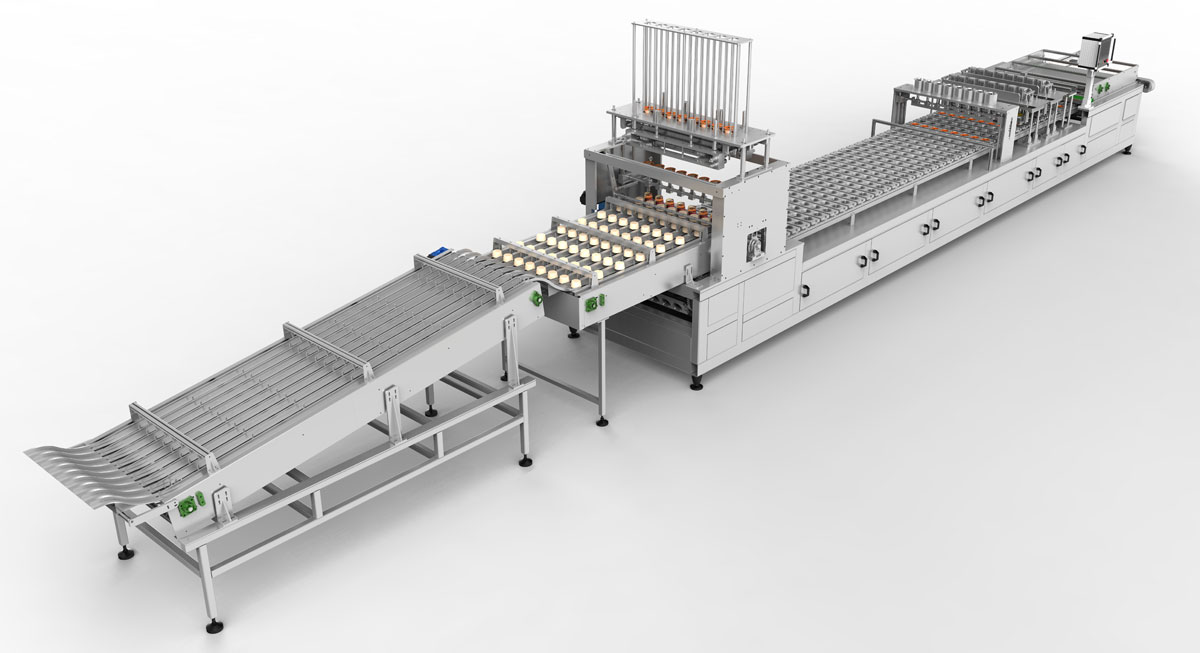

Solution and Brand Advantages: Core Value of Bucket Instant Noodle Paper Bowl Sealing Machine

To address the sealing pain points of bucket instant noodles, bowl instant noodles, and similar products, our Bucket Instant Noodle Paper Bowl Sealing Machine (PJZN-6 Series Semi-Automatic Bowl Noodle Sealing Machine) — as a professional food and beverage packaging equipment — is designed in synergy with bowl instant noodle/vermicelli/cup noodle sealing equipment and noodle cake feeding systems. It accurately solves sealing challenges and meets the needs of large-scale production.

Core Advantages: High Efficiency, Stability, and Adaptability to Diverse Needs

• Automation Reduces Labor and Improves Efficiency: Equipped with automatic lid suction, lid placement, and cup output devices, the sealing process requires minimal manual intervention. It can be directly connected to the production line to avoid product backlogs. Meanwhile, it is compatible with the rhythm of the noodle cake feeding process, ensuring smooth connection between front-end and back-end procedures.

• Precise Temperature Control for Stable Sealing Quality: The automatic sealing system is equipped with a PID intelligent temperature control system, with independent temperature control for each sealing head. The surface of the sealing aluminum mold is coated with Teflon non-stick coating, effectively preventing loose seals (liquid leakage) or overly tight seals (deformation).

• Flexible Adaptability to Multi-Specification Products: The standard frame is suitable for paper bowls/plastic bowls/paper cups/plastic cups with a caliber of 100-150mm. No major equipment modification is needed when switching product specifications — quick adjustment can be achieved by simple parameter settings.

• Stable Transmission Ensures Continuous Production: The transmission and template traction system adopts a linear stepping system composed of a drive servo motor and reducer, combined with a positioning device, ensuring accurate template traction and stable operation. The automatic cup output device guarantees upright cup output, seamlessly connecting to the subsequent production line and eliminating the “automation gap”.

• Safe, Reliable, and Easy to Maintain: The electrical control system is equipped with fault alarm prompts, emergency stop devices, and electrical protection. It provides real-time alerts when equipment malfunctions (e.g., lid jamming, abnormal temperature control), reducing troubleshooting time. The frame is made of carbon steel welding with an outer stainless steel cover; the upper sealing mold is made of aluminum alloy with a Teflon non-stick coating on the surface; other components all meet food hygiene standards, enabling convenient daily cleaning and maintenance.

If your factory is troubled by low sealing efficiency, unstable quality, or slow specification switching in bucket/cup noodle production, or if you need a continuous production line that adapts to both noodle cake feeding and sealing, please feel free to consult us. Our Bucket Instant Noodle Paper Bowl Sealing Machine will provide you with a precise solution to optimize your production process. Click to consult for equipment parameters, adaptation plans, and cases.

[You Deserve a Better Production Method]

Click to inquire → Get your Customized Food & Beverage Packaging Line Solution

Hangzhou Panji Intelligent Equipment Co., Ltd. Tel/Wechat/Whatsapp +86 18989472188 [email protected]