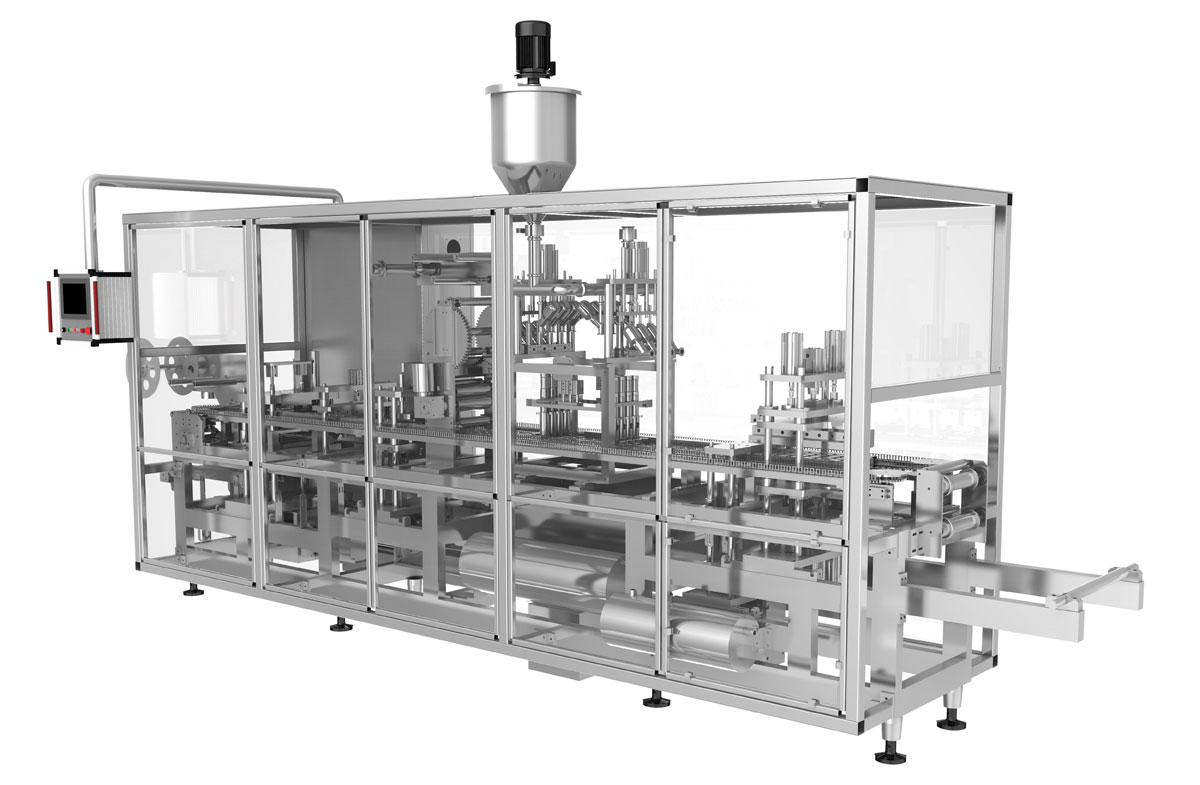

As a factory procurement manager, are you often troubled by issues such as poor equipment connection and low efficiency in the production process of plastic cup packaged mineral water? From plastic sheet cup making, filling, and sealing to subsequent boxing, the performance of equipment in each link directly affects the overall efficiency of the production line. Choosing the right integrated equipment can make the production process smoother.

Industry Pain Points: Common Problems in Plastic Cup Packaged Mineral Water Packaging

Amplified Consequences: Small Problems Cause Chain Losses

Solutions and Brand Advantages: Integrated Equipment Solves Pain Points

Core Advantages: Efficient Integration and Intelligent Linkage

If your factory is troubled by the packaging efficiency and cost issues of plastic cup packaged mineral water, or plans to upgrade the production line to achieve full-process automation, welcome to consult. Our fully automatic equipment will help you connect all production links and promote cost reduction and efficiency improvement. Click to consult for equipment parameters, cases and customized solutions.

[You Deserve a Better Production Method]

Click to inquire → Get your Customized Food & Beverage Packaging Line Solution

Hangzhou Panji Intelligent Equipment Co., Ltd. Tel/Wechat/Whatsapp +86 18989472188 [email protected]