Factory procurement managers, have you repeatedly encountered obstacles in the production of new food ingredients such as popping boba and crystal balls? As innovative ingredients in the beverage, baking, catering and other industries, the production efficiency and quality of popping boba directly affect product competitiveness. However, underperforming packaging equipment often causes enterprises to miss market opportunities.

Industry Pain Points: Common Obstacles in Popping Boba Production

In the large-scale production of popping boba, crystal balls and fruit pearls, do these equipment pain points trouble you?

Unstable forming, with popping boba having inconsistent diameters (deviating from the standard range of 5-12mm) and uneven thickness of the outer membrane, resulting in varying textures and affecting product consistency.

Slow production speed, with a single head forming less than 50 times per minute, making it difficult to meet the production capacity requirements of large and medium-sized enterprises and dragging down the progress of the entire production line.

Low degree of automation, relying on manual connection from raw material preparation to filling and sealing, which not only increases labor costs but also easily leads to pollution risks (such as raw material exposure and unqualified hygiene) due to operational errors.

Poor adaptability, unable to flexibly switch between multi-flavor production (such as strawberry, passion fruit, mango, etc.), requiring major adjustments to equipment parameters during production changes, which is time-consuming and labor-intensive.

Disconnection in the entire line, with links such as forming, solidification, filling and sterilization being disconnected, forming “production islands” and failing to achieve integrated production from raw materials to finished products.

Amplified Consequences: Small Problems Lead to Chain Losses

These equipment shortcomings, seemingly local, can actually trigger a series of chain reactions, causing enterprises to pay a heavy price:

- Unqualified quality: The outer membrane of popping boba is easy to break or too hard, resulting in poor taste experience, leading to an increase in customer complaints and damage to brand reputation; excessive diameter deviation affects the visual presentation of beverages and is rejected by downstream customers.

- Insufficient production capacity: The low forming efficiency of a single head leads to the daily output of the entire line being less than 100,000 pieces, missing the golden period for new product launches and watching competitors seize the market.

- High costs: There are many manual intervention links, and each production line needs to be equipped with 3-4 additional workers, increasing the annual labor cost by 150,000-200,000 yuan; frequent equipment adjustments lead to a raw material waste rate of more than 8%, further compressing profit margins.

- Restricted innovation: Unable to quickly switch to multi-flavor production, it is difficult to respond to market demand for characteristic popping boba such as strawberry, yogurt and orange, and the product iteration speed lags behind peers.

Solution: Fully Automatic Production Line Solves Problems and Enables Efficient Production

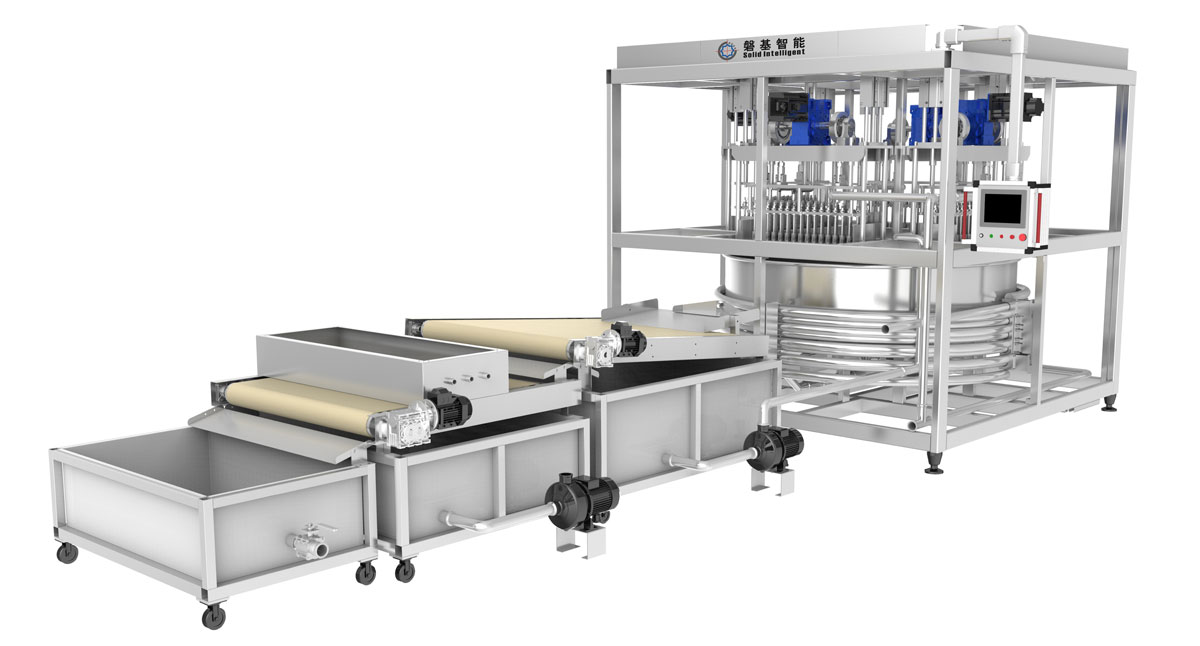

In response to the production pain points of popping boba, crystal balls and popping eggs, our company has developed a fully automatic popping boba crystal ball fruit pearl production line (including popping egg popping boba forming and filling production line), integrating advanced technologies at home and abroad to provide an integrated solution for large and medium-sized food and beverage enterprises.

Brand Advantages: Efficient, Stable and Adaptable to Multi-Scenario Needs

High-precision forming: The entire line consists of raw material juice blending and supply system, titration system, forming system, etc. A single head forms 60-70 times per minute, and the diameter of popping boba is stable at 5-12mm. The outer membrane is uniform and elastic, ensuring a consistent chewy taste.

Full-process automation: From raw material preparation to sterilization, filling and sealing, the entire line operates fully automatically. The PLC control system accurately regulates each link, reducing manual intervention, lowering pollution risks and meeting food hygiene standards.

Flexible switching of multiple flavors: Supports the production of popping boba with multiple flavors such as strawberry, passion fruit, mango and yogurt. During production changes, parameters can be quickly adjusted through the system without large-scale equipment modification, meeting diversified market demands.

High adaptability: Can be connected to downstream packaging links, adapting to the subsequent processing of different application scenarios such as beverages, frozen products and baking, creating a complete production chain from raw materials to finished products for enterprises.

If your enterprise is planning to layout popping boba and crystal ball products, or wants to upgrade the existing production line to improve efficiency, welcome to consult. Our fully automatic popping boba production line will solve problems such as unstable forming and low efficiency for you, helping your products seize market opportunities. Click to consult for equipment parameters and customized solutions.

[You Deserve a Better Production Method]

Click to inquire → Get your Customized Food & Beverage Packaging Line Solution

Hangzhou Panji Intelligent Equipment Co., Ltd. Tel/Wechat/Whatsapp +86 18989472188 [email protected]