In recent years, fruit pellet products such as popping boba, magic bean popping balls have swept the food and beverage market, winning acclaim in catering, frozen desserts, baking, and other fields with their round and transparent appearance and rich, fragrant taste. However, many factories are facing difficulties in the production process.

• Traditional production equipment struggles to precisely control the diameter of fruit pellets, which typically ranges from 5 – 12mm, resulting in inconsistent molding quality.

• Unstable ratios in raw juice blending lead to significant variations in product flavors.

• Moreover, the low degree of automation in the production process means that manual operations are not only inefficient but also prone to hygiene risk .

Is your factory also troubled by these issues?

These industry pain points are severely hindering enterprise development . The lack of precision in production equipment leads to a large number of defective products, increasing raw material waste costs. Flavor inconsistencies directly affect the consumer experience, damaging brand reputation and causing customer loss. The low-automation production model fails to meet the explosive growth in market orders and further squeezes profit margins due to high labor costs. In an intensely competitive market environment, enterprises that cannot rapidly improve the production efficiency and quality of fruit pellets risk being eliminated and missing out on industry development dividends.

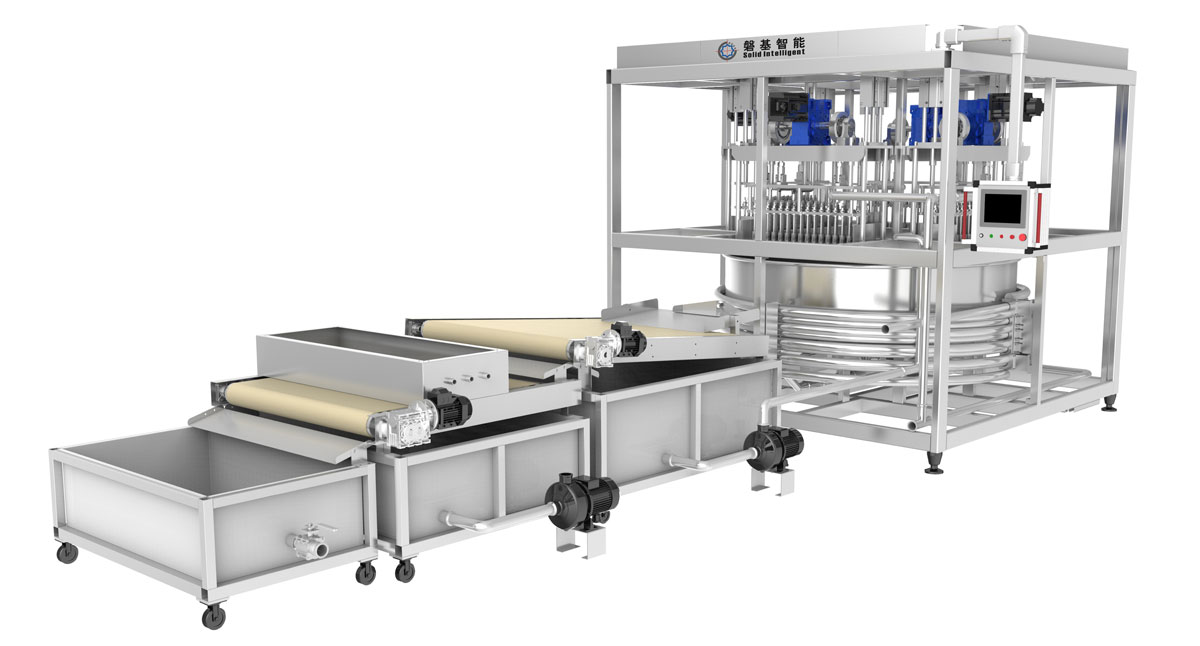

Looking to break free from these dilemmas and achieve efficient and stable fruit pellet production? Our high-speed production lines for popping boba, magic beans, and popping balls are the key to solving these problems! Comprising a raw juice blending and supply system, titration system, molding system, filtration system, cleaning and curing system, filling and sealing system, sterilization system, and PLC control system, these production lines integrate advanced domestic and international technologies and adopt a fully automated integrated design. We also offer flexible customization services to meet your diverse needs.

Our production lines not only ensure high speed and stability, with each molding head capable of 60 – 70 formations per minute, significantly boosting production capacity. They can also be customized to produce a variety of flavors according to market demands, such as strawberry magic beans, passion fruit magic beans, mango magic beans, yogurt magic beans, and orange magic beans. The precise raw juice blending and supply system, along with the titration system, guarantee consistent flavor and premium quality for every fruit pellet. The stable molding system ensures uniform diameter specifications and a round, translucent appearance. The high degree of automation reduces manual intervention, ensuring production hygiene and safety while cutting labor costs. Whether for adding to beverages and milk tea, decorating western-style pastries, or used in prepared foods, these production lines can easily adapt to different application scenarios, providing a solid production foundation for large and medium-sized food and beverage enterprises.

The market for fruit pellets has broad prospects, and opportunities are fleeting! Don’t let production challenges hold back your enterprise’s development. Contact us now to obtain an exclusive high-speed fruit pellet production solution, customize a production line with unique flavors, seize market opportunities, and embark on a new journey of high-efficiency profitability!

[You Deserve a Better Production Method]

Click to inquire → Get your Customized Food & Beverage Packaging Line Solution

Hangzhou Panji Intelligent Equipment Co., Ltd. Tel/Wechat/Whatsapp +86 18989472188 [email protected]