Gerentes de compra de fábrica, Você está sempre perturbado por esses problemas no processo de embalagem de alimentos e bebidas? A eficiência da produção não pode ser melhorada, A qualidade do limite é instável, e a adaptabilidade do equipamento é ruim… Não entrar em pânico. Este artigo, cheio de informações úteis sobre o equipamento de embalagem de alimentos e bebidas, está especialmente escrito para resolver seus pontos de dor.

Pontos de dor da indústria: Armadilhas de eficiência e qualidade no processo de embalagem

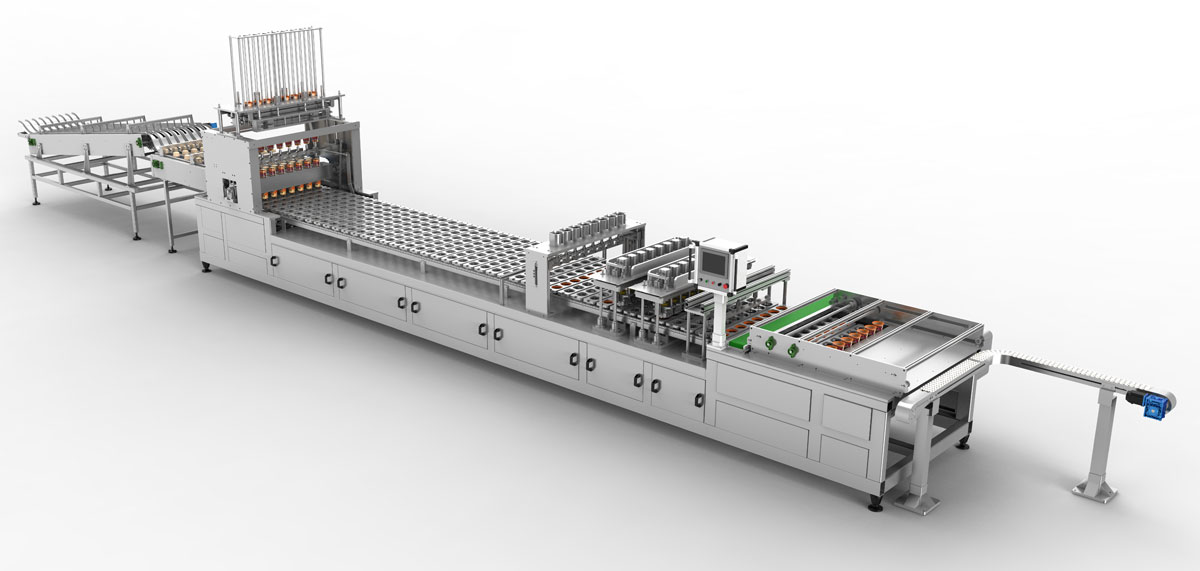

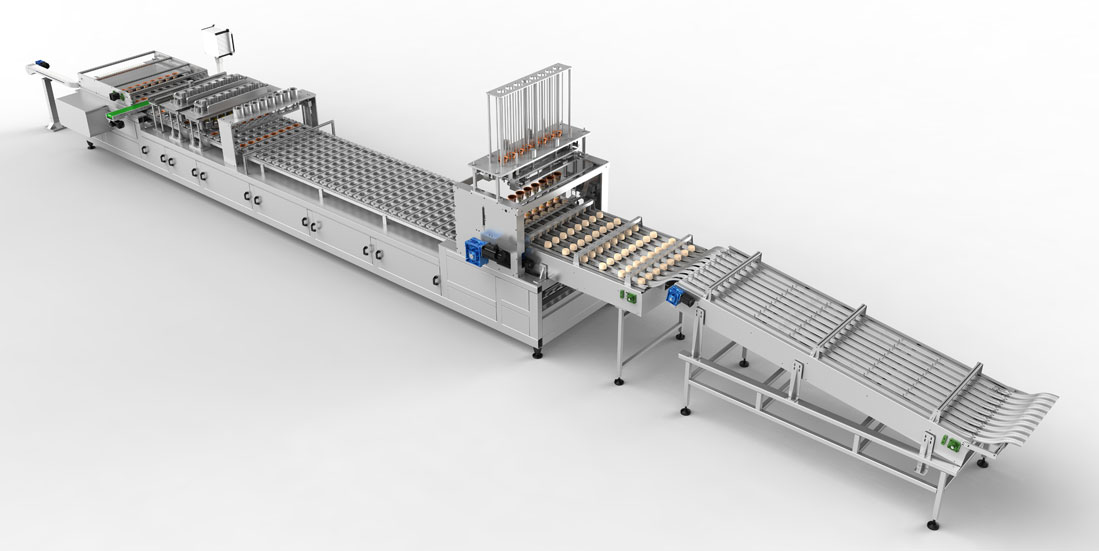

Na produção de fábricas de alimentos e bebidas, Se o equipamento de embalagem não estiver à altura, Haverá muitos problemas: Ao querer produzir produtos como barril – macarrão instantâneo embalado e aletria de macarrão instantâneo, O equipamento não pode dispensar automaticamente os bolos de macarrão e pacotes de tempero, e a intervenção manual é necessária, o que reduz bastante a eficiência; Durante o capacão, ou a vedação não é apertada, levando a vazamentos e umidade líquidos, ou a velocidade de capela é lenta, desacelerando o ritmo de toda a linha de produção; Ao encontrar tigelas de papel/xícaras e tigelas de plástico/xícaras de diferentes calibres, A adaptabilidade do equipamento é ruim, e a mudança de produção requer muito ajuste, atrasar o tempo de produção e aumentar os custos de trabalho e material.

[Você merece um método de produção melhor]

Clique para perguntar → Obtenha sua comida personalizada & Solução de linha de embalagem de bebidas

Hangzhou Panji Intelligent Equipment Co., Ltd. Tel/WeChat/WhatsApp +86 18989472188 [email protected]